How to make flame retardant fabric?

First, you can add a flame retardant coating to the surface of cotton, linen and other fabrics. Another process is to infiltrate the flame retardant into the interior of the fabric. Both methods can achieve the flame retardant effect. Different flame retardant processes can achieve The effects are also different. The cost of adding flame retardants to fabrics is relatively low.

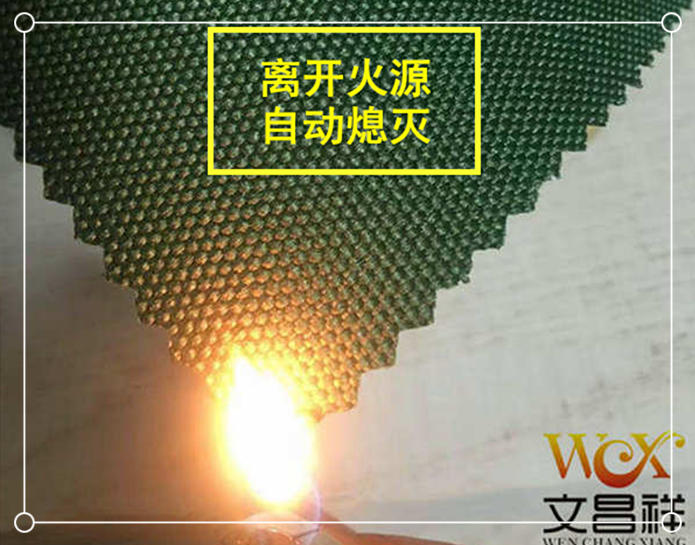

600D flame-retardant fabric stops burning after isolating the fire source, while fire-retardant fabrics generally do not burn Yes, this is the most essential difference between them. Post-finishing flame retardant is mainly used for cotton or fabrics with a low proportion of chemical fibers, and flame retardant fibers use various chemical fibers as carriers to give full play to the excellent properties of various chemical fibers.

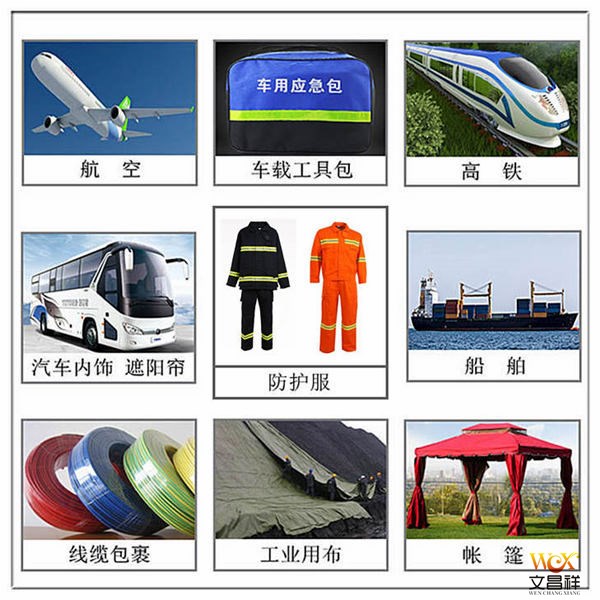

Flame-retardant fabrics are not used in the clothes we wear every day, mainly in chemical protective clothing, firefighting suits, astronaut suits or racing suits. There are applications on. Of course, some home curtains or carpets also use flame retardant fabrics.

1. Industrial flame retardant protective workwear (used in petroleum, petrochemical, chemical and other industries); 2. Fire fighter combat uniforms and command uniforms; 3. Decorative supplies for homes and hotels , such as: carpets, curtains, bedding, etc.; 4. General clothing, especially children’s clothing, pajamas, etc.; 5. Arc protection clothing; 6. Space suits; 7. Racing suits.

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p