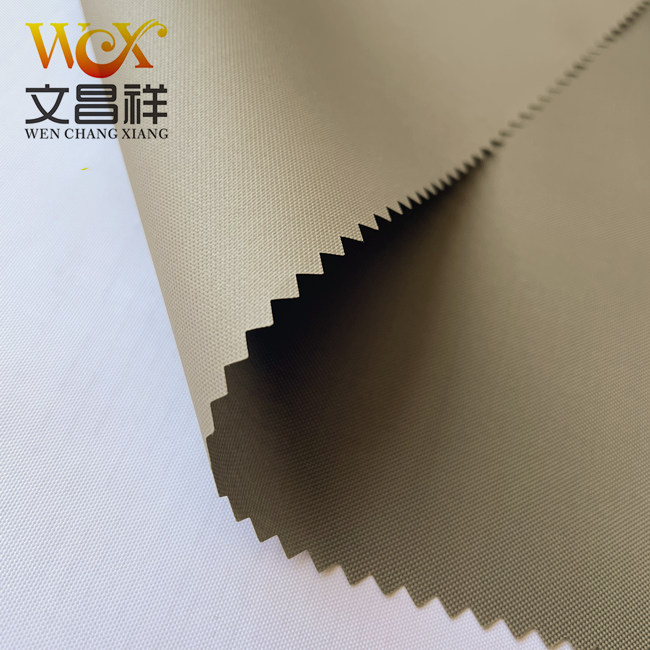

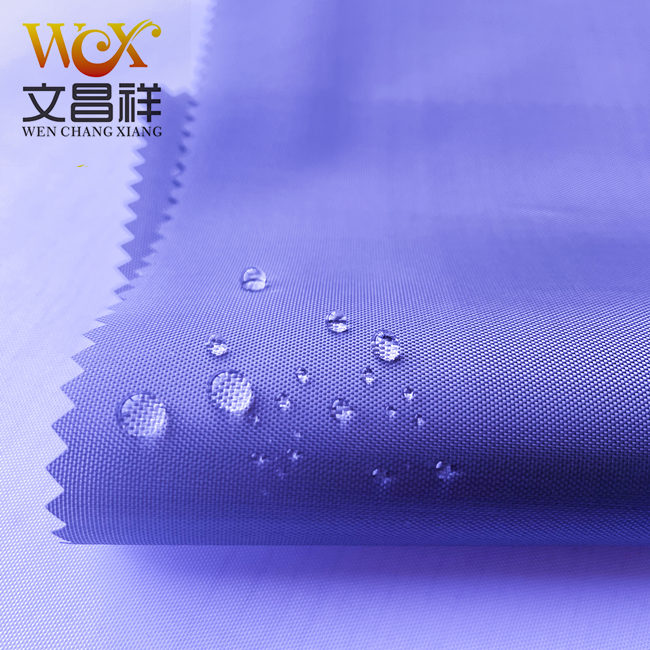

It is understood that the fabric is made of DTY silk 600*600D as raw material, woven on a water-jet loom, and processed through multiple processes such as pre-shrinking, shaping, dyeing, PVC coating, and waterproofing agent treatment. It has won the trust of many consumers with its unique advantages such as soft and smooth feel, bright color, good waterproofness, durability and resistance to wrinkles. The cloth width is 3750px, the weight is 230 (g/m2), and the colors are rich. This product is mainly used for making bags, sports and leisure products, outdoor products and other materials.

600D waterproof oxford cloth Compared with ordinary Oxford cloth, it has added waterproof and soft functions, which can extend the service life. The colors are rich and consumers have a lot of choice. It has become the main fabric of choice for luggage manufacturers everywhere.

According to customers The requirements are woven on a flat machine with 600Dx600D yarn count, density 13×13, square meter weight 230, and white embryo 600D Oxford cloth for post-processing (dyeing, waterproofing process) in the dyeing and finishing factory. The finished semi-finished product has the advantages of soft hand feel, light fabric, resistance to twisting, good waterproofness, tear resistance, and anti-static. This customer is currently using a mountaineering backpack fabric.

Use of 600D waterproof Oxford cloth: Depending on the post-processing process of 600D Oxford cloth, it can also be used to make trolley cases, business bags, camping tents, camping mats, tarpaulins, beach chairs, parasols, etc.

Oxford cloth What are the specifications? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p