Luggage cloth is generally made using specifications such as 420d, 600d, and 1680d. Relatively speaking, 1680d Oxford cloth is the most wear-resistant. 420D Oxford cloth: The warp of this fabric is made of nylon air-conditioned yarn, and the weft is made of 160D nylon air-conditioned yarn. 420D Oxford cloth: It has the advantages of soft feel, strong drape, novel style, waterproof and fireproof performance, etc. The fabric is based on the market with the advantages of non-fading and non-deformation.

600 is Number, denier (D) represents the weight of the silk thread per unit length. Denier (D) = g/Lx9000. g is the weight of the silk thread (grams), L is the length of the silk thread (meters), the higher the value, the greater the same area of fabric. The heavier it gets. Mountaineering bags are generally between 300D-600D.

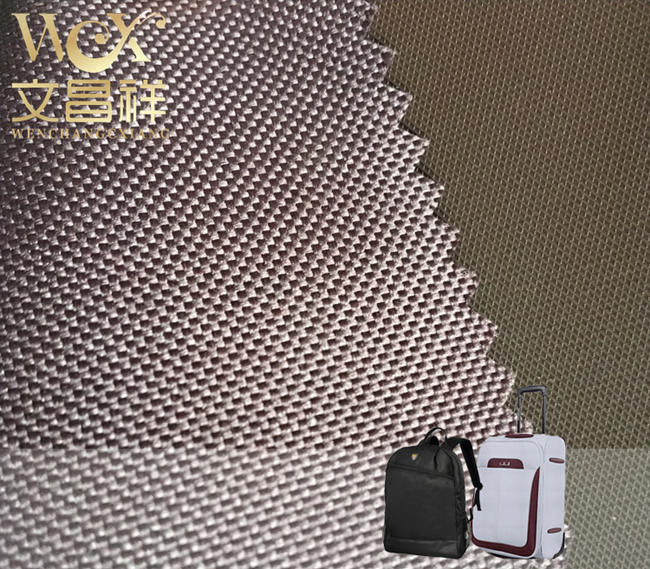

1680D Double Strand Oxford The cloth has extremely strong tensile strength and wear resistance, and also has extremely high density and waterproofness. Its waterproof performance generally reaches the current IPX3 or IPX4 waterproof level. In addition, 1680D double-strand Oxford cloth has a noble luster. 1680D material is now generally used as fabric for high-end outdoor products or bags. Post-finishing is mostly calendered PVC, polyurethane, PU coating, EVA composite, and also includes transfer printing, hot rolling, screen printing, etc. Most of the 1680D double-ply Oxford cloth produced by domestic manufacturers is polyester large shiny filament.

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p