There are two ways to achieve fire-retardant and fire-retardant effects on fire-retardant fabrics. One is to copolymerize flame retardant monomers with polymers or add flame retardants to the polymers, and then make a blend through miscibility processing. fiber, and then woven into flame-retardant fabrics; another method is the post-finishing process, which is to treat the Oxford cloth with flame retardants by spraying, padding or coating. The flame retardants will emit flames when encountering fire. Physical and chemical reactions to achieve flame retardant effect.

How to evaluate the flame retardant performance of flame retardant fabric?

On the one hand, it depends on the burning performance of the fabric: judging from the burning rate of the flame retardant Oxford cloth, that is, the fabric that has been flame retardant finished according to the prescribed method and The flame is exposed to the flame for a certain period of time, and then the flame is removed, and the time the flame-retardant cloth continues to burn with fire and the time without flame burning is calculated, as well as the degree of damage to the fire-retardant cloth. The shorter the flame burning time and the flameless burning time, and the lower the degree of damage, the better the flame retardant performance of the fire retardant and flame retardant cloth; otherwise, the flame retardant performance of the fire retardant and flame retardant cloth is poor.

On the other hand, it is judged by the oxygen index: flame-retardant cloth requires oxygen to burn, and the oxygen index is an expression of the oxygen required for fiber burning, so it is judged by Measuring the oxygen index can determine the flame retardant performance of the flame retardant fabric. The higher the oxygen index, the higher the oxygen concentration required to maintain combustion, which means it is more difficult to burn: this index can be used to maintain candle-like burning of samples in nitrogen and oxygen mixed gases. It is expressed as the minimum volume percentage of oxygen required. If the oxygen index is less than 20%, it is a flammable fiber; if the oxygen index is between 20 and 26%, it is a flammable fiber; if the oxygen index is between 26 and 34%, it is a flame-retardant fiber; if the oxygen index is above 35%, it is a non-flammable fiber.

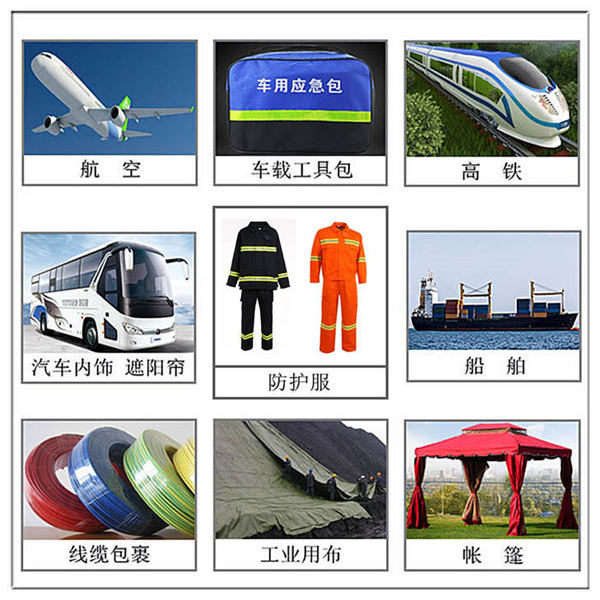

Uses of flame-retardant fabrics

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., have temporary flame retardant effect, semi-permanent flame retardant effect and durable flame retardant effect. They can also be waterproof, flame retardant, PVC/PU coating, etc. according to customer needs. For silver coating, lamination and other treatments, you can contact the online customer service on the website or leave a message. We will provide dedicated service to meet all your needs!

</p