Textiles | Aramid fiber

Textiles | Aramid fiber

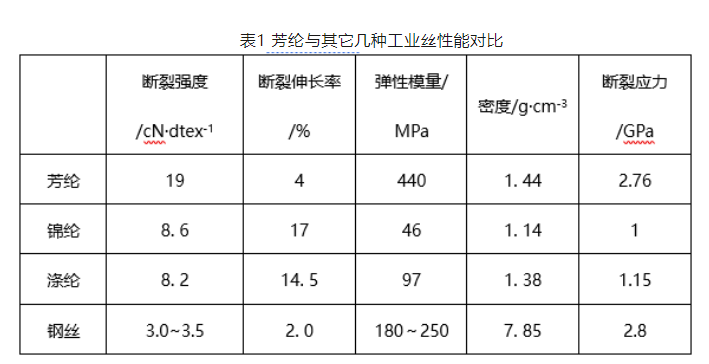

Aramid fiber has the characteristics of high strength, high modulus, high temperature resistance, acid and alkali resistance, light weight, good insulation and aging resistance. Its strength is 5 to 6 times that of steel wire, and its modulus is 5 times that of steel wire or glass. It is 2 to 3 times that of fiber, twice as tough as steel wire, and weighs only about 1/5 of steel wire. It is often used as a reinforcement in the preparation of high-performance composite materials and occupies an important position among high-performance fibers.

Table 1 Picture comparing the performance of aramid fiber and other industrial yarns

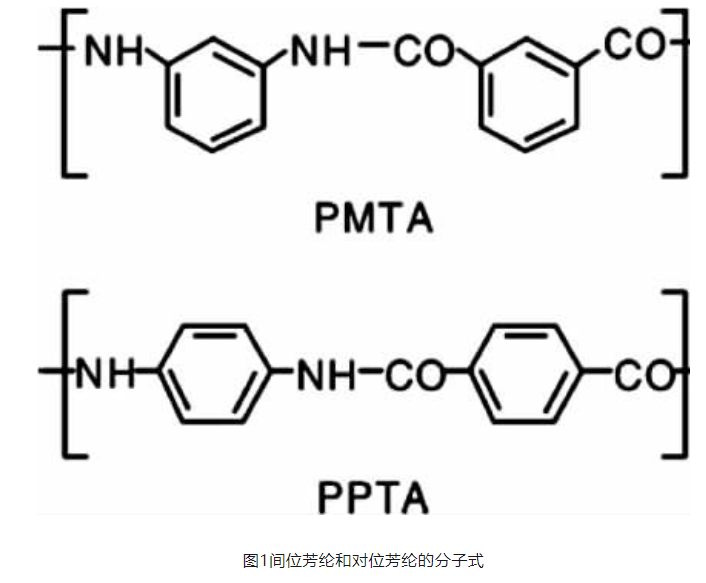

Aramid fiber mainly includes fully aromatic polyamide fiber and heterocyclic aromatic polyamide fiber, which can be divided into three types: ortho-aramid, para-aramid (PPTA) and meta-aramid (PMTA). Among them, Industrialized products mainly include meta-aramid and para-aramid. The main difference between these two types of aramid lies in the different connection positions of the amide bond and the C atom on the benzene ring.

Figure 1 Molecular formulas of meta-aramid and para-aramid

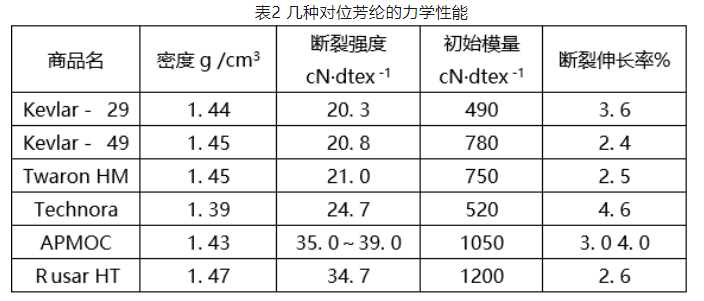

Para-aramid, that is, polyparaphenylene terephthalamide (PPTA) fiber, called aramid 1414 in my country, is a linear polymer in which more than 85% of the amide bonds in the molecular chain are directly bonded to the aromatic ring. Para-aramid fibers mainly include Kevlar fiber from DuPont of the United States, Twaron and Technora fibers from Teijin Company of Japan, and Taparan fiber from Yantai Taihe New Materials. It is the world’s first fiber made from polymer liquid crystal spinning solution, ushering in a new era of high-performance synthetic fibers. Among the existing high-performance fibers, para-aramid is one of the fibers with the best comprehensive performance. Its most prominent features are high strength, high modulus and high temperature resistance. Taking Kevlar fiber as an example, its strength is 3 times that of steel wire and 4 times that of polyester industrial yarn. Its initial modulus is 4 to 10 times that of polyester industrial yarn and 10 times that of nylon. The mechanical properties of several para-aramid fibers are shown in Table 2.

Table 2 Pictures of mechanical properties of several para-aramid fibers

Para-aramid has a high glass transition temperature (Tg) and thermal decomposition temperature (Table 3), good thermal stability, and can still maintain high strength at high temperatures; the fiber has a high limiting oxygen index (LOI) , good flame retardancy. It was experimentally measured that the shrinkage rate of para-aramid fiber at 150℃ is 0, and it can still maintain 65% of its original strength at a high temperature of 260℃. When exposed to an environment of 300℃ for a short period of time, the mechanical properties of the fiber are almost unaffected. Embrittlement and degradation will not occur at low temperatures.

Table 3 Thermal properties and combustion properties of para-aramid fiber

Although para-aramid has many excellent properties, there are also some shortcomings. Due to the weak intermolecular force of para-aramid, the fiber surface lacks active groups, resulting in low compressive strength and compressive modulus, and low bonding strength at the fiber-resin interface. There are polar groups such as amide groups in the molecular structure of para-aramid fiber, and the fiber has poor hygroscopicity. After moisture absorption, the intrusion of water molecules destroys the hydrogen bonding between molecules, resulting in a decrease in fiber strength and a decrease in the bending and compression properties of the composite material. All decreased. In addition, para-aramid is not resistant to strong acids and alkalis, and has poor light resistance and UV resistance.

Meta-aramid, that is, polymeta-phenylene isophthalamide (PMTA) fiber, also known as aramid 1313 in my country, was first successfully developed by Nomex by DuPont in the United States and achieved industrial production in 1967. There are also Conex from Teijin, Tametar from Yantai Taihe New Materials, etc. Meta-aramid is the fastest growing seed crystal among organic high-temperature resistant fibers. The fiber molecules are composed of amide groups interconnected with meta-phenyl groups. The molecular chain is linearly zigzag. Due to the strong hydrogen bonding between molecules, the fiber It has excellent flame retardancy, thermal stability, radiation resistance and other properties.

Meta-aramid is a flame-retardant fiber that will not spontaneously ignite or melt in the air and will self-extinguish after leaving the flame. Fiber