Humidification and drying of cotton seed cotton drying equipment

(4) Evaluation of the performance of the cotton dryer

The evaluation of the performance of the cotton dryer should be based on the “National Industry Standard for Dryers” and considered from the perspective of usefulness. That is, the main indicators to evaluate the performance of the dryer are energy consumption, water removal rate after one drying, drying unevenness and safe operation rate.

1. Energy consumption

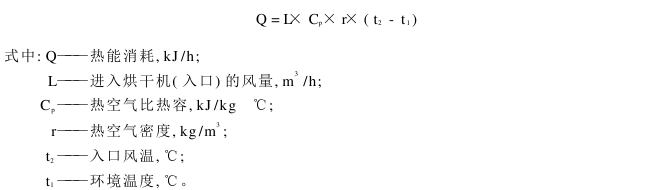

Energy consumption includes thermal energy consumption and electrical energy consumption. Thermal energy consumption is calculated by the following formula:

So far, the drying of cotton depends on the increase in the temperature of the conveyed air volume. Therefore, the power consumption mentioned here refers to the operation of the cotton dryer itself and the fan required in the process. Electrical power consumption, that is, the electrical power consumption of hair dryers and suction fans.

2. Water removal rate after primary drying

The water removal rate after primary drying is not as high as possible, because the moisture content of the cotton entering the sawtooth gin is 7% to 9%, which is the optimal working condition for the ginning system. ,At this time, the yield of cotton fiber is high, the quality is good, the machine works stably, and the failure rate of equipment and process is low. Therefore, for super-water molecular cotton, the best moisture content is 7% to 9% after one drying.

3. Drying unevenness

Drying unevenness refers to the difference between high moisture content and low moisture content of cotton after drying. The standard stipulates that drying unevenness cannot exceed 1%, which means that drying is required The moisture content of the cotton after drying in the dryer should be completely consistent, and it should not be dry or wet. Otherwise, it will affect the subsequent finishing of cotton.

4. Safe operation rate

The dryer should not be blocked and can work continuously for a long time. The use of the dryer should not affect the normal production of the ginning factory.

AAASDFWFWFWE