Lint cleaning Use and maintenance of lint cleaning machine

Lint cleaning machines have relatively high technical content and strict manufacturing precision and operation requirements. Therefore, the correct use and maintenance of lint cleaning machines is particularly important.

(1) Correct use of lint cleaning machine

(1) The moisture content of lint should be less than 8% during the load test of a new vehicle. Before the test, check whether the valve position of the four-way valve is correct.

(2) Start-up sequence: suction fan → licker-in → cotton feeding system → cotton suction fan → gin. If the gin is started first, the working box should be opened, and it can be operated with load only when it is confirmed that there is no residual lint in the lint path.

(3) During the test run, you should observe:

① Check whether the cotton batting is uniform through the front fence;

② Open the movable panel to see whether there are leaks and impurities sucking back; ③ Check the wool from the rear Check whether there are flying flowers between the upper and lower brushes.

After the test run is completed, the gin should be stopped first and only when there is no remaining lint in the lint road can it be stopped. The parking sequence is opposite to the driving sequence.

(4) When new equipment starts production, the cotton with a moisture content of less than 8% should be sorted. Only after the continuous working time exceeds 200 hours can the cotton with a moisture content of more than 8% be sorted.

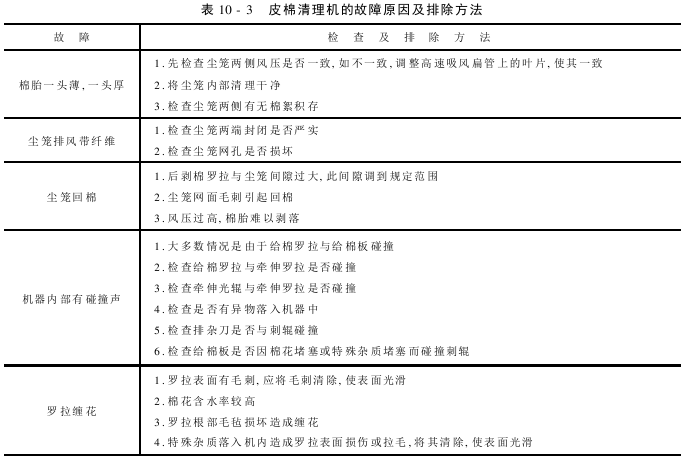

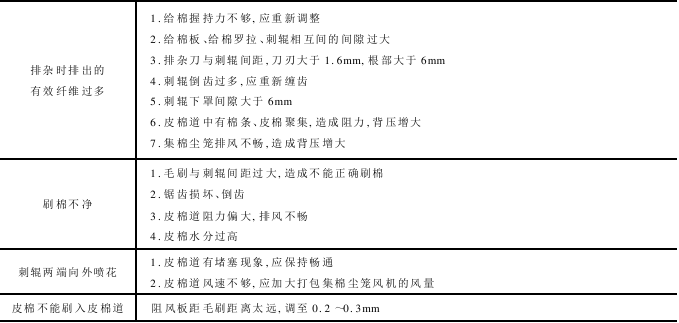

(2) Troubleshooting of lint cleaning machine

The causes and troubleshooting methods of lint cleaning machine are shown in Table 10-3.

(3) Safety maintenance and maintenance of lint cleaning machine

(1) All components and parts should be carefully inspected before starting the machine. Check whether the parts are installed firmly and correctly, and whether the rotating parts are sensitive. Then close and lock the protective door.

(2) The motor and electrical appliances should have reliable protection devices, and a main switch should be installed. In case of emergency, the power supply and air source should be cut off immediately.

(3) The machine has not stopped and it is not allowed to do the cleaning work. When you find that the cotton batting is uneven or there are many flowers hanging in the machine, you should stop the machine for processing.

(4) When foreign matter enters the machine or a burnt smell is detected, the machine should be shut down to prevent fire.

(5) Bearings should be cleaned and lubricating oil replaced every quarter. Clean sprockets and gears quarterly.

(6) The licker-in has a large area of inverted teeth. When two or more consecutive inverted teeth exceed 3,000 teeth, a new rack should be replaced.

(7) Check whether the fasteners are loose at any time. Check once a day in the first year and once every 3 to 5 days in the second year. Mainly check the licker-in, brush, cotton feed plate, and cotton feed roller pin. Fastening bolts at. Always check the sensitivity of each adjustment part.

(8) The inside and outside of the dust cage, the debris removal knife and other parts should be cleaned once every shift to prevent damage. Open the protective cover and clean the lint once every 1 to 2 weeks. Clean the cotton seeds and cotton fibers on the licker-in once a week.

Correct use and maintenance can reduce the occurrence rate of equipment failure, reduce the number of replacements of wearing parts, and extend its service life.

AAAERT5Y4375JTY