Scrap cleaning and recycling Types of scrap cleaning machinery

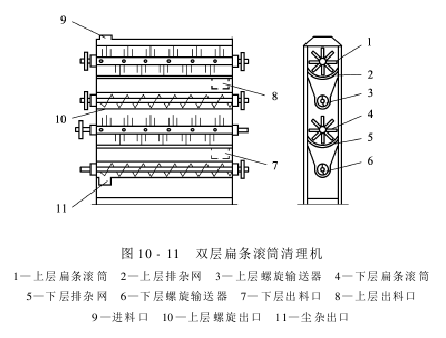

(1) Double-layer flat roller cleaning machine

The infertile lint discharged from the cotton gin, the impurity velvet discharged from the stripping machine, and the scraps discharged from the cleaned cotton can all be cleaned by the double-layer flat roller cleaning machine ,The structure is shown in Figure 10-11.

Scraps It is fed from the feed port and is struck by the rotating upper flat bar roller to loosen it. Pushed by the spirally arranged flat bars, it slowly moves toward the exit along the axial direction of the drum. During the impact and movement of the scraps, due to the smaller binding force between impurities and other components, larger density, smaller particle size, etc., dust, small infertile particles and some short fibers are discharged from the upper debris discharge net. It falls into the upper spiral conveyor and enters the lower flat roller through the upper sample outlet to continue cleaning. The cleaned fibrous materials and impurities are thrown out from the lower discharge port and dust outlet respectively. The mesh of the lower impurity discharge net is smaller than that of the upper impurity discharge net, which can further recover the shorter fibers discharged by the upper impurity discharge net.

The double-layer flat roller cleaning machine has a wide range of uses. In addition to cleaning infertile lint and impurity lint, it can also clean fly lint and waste lint. However, the mesh of the lower layer of debris removal net should be 3mm × 3mm. .

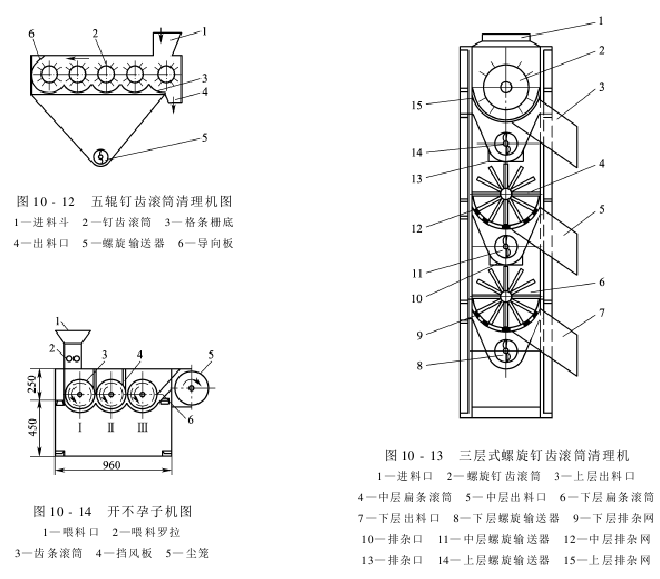

(2) Five-roller nail-toothed drum cleaning machine

The five-roller nail-toothed drum cleaning machine is a device for continuously cleaning infertile children, as shown in Figure 10-12.

Five rollers The nail drum cleaning machine is mainly composed of a nail drum with a diameter of 350mm, a grating bottom, and a screw conveyor. The nail drum is composed of a steel plate cylinder with a diameter of 250mm and 12 rows of 50mm long conical nail teeth fixed around it. It is driven by a sprocket and rotates in the same direction, with a speed of 220~250r/min. The bottom of the grating is made of elastic steel wires with a diameter of 4cm mounted on the arc plate. The clear distance between the gratings is 5mm, and the distance between the gratings and the tooth ends of the nail roller is 10mm.

The infertile particles discharged from the cotton gin are sucked by the ventilator to the infertile dust cage and then fall into the feed hopper. With the rotation of the nail-toothed roller, they move to the guide plate on the upper part of the roller and follow the guide. The plate moves downward along the bottom of the grid and is discharged from the discharge port. During the cyclic impact process, the impurities pass through the gaps between the grids and fall on the screw conveyor and are discharged out of the machine.

(3) Three-layer spiral nail drum cleaning machine

The three-layer spiral nail drum cleaning machine is mainly used to clean the impurity velvet discharged from the stripping machine. In addition to recycling short velvet, it can also be recycled The structure of cotton kernels and small cotton seeds is shown in Figure 10-13.

The upper cleaning mechanism consists of a spiral nail roller with a diameter of 400mm and an upper impurity discharge net with a mesh diameter of 7 to 8mm (a grate can also be used). The middle-level cleaning mechanism consists of a middle-level flat roller with a diameter of 300mm and a debris removal net with a mesh diameter of 5mm. The lower cleaning mechanism consists of a lower flat roller with a diameter of 300mm and a lower impurity discharge net with a mesh diameter of 3mm.

(4) Double rack and drum cleaning machine

The double rack and drum cleaning machine is a machine that can not only extract and clean infertile long fibers, but also clean and strip impurities of velvet. In addition to the main machine, it is also equipped with a ventilator, a feed dust cage, a five-roller nail drum cleaning machine and other equipment. Through the air flow pipe, the infertile particles discharged from the cotton gin can not only be processed continuously, but also individually. Since there is a recycling suction pipe at the entrance of the trash discharge plate, the trash discharge efficiency can be fully exerted and the fiber recovery rate can be improved.

The double rack roller cleaning machine is mainly composed of a frame, a conveyor roller, a cotton feed roller, a rack roller, a dust cage, a cotton feed plate and other components.

The pure sterile material discharged from the front and rear rack rollers enters the rear cleaning machine through the airflow duct to extract Class I cashmere.

(5) Open the infertility machine

The pure infertility after extracting long fibers is still a good fibrous raw material and can be processed into cotton linters. The infertile fetus machine is a device used to shred infertile fetuses. Its structure is shown in Figure 10-14.

The cleaned infertile nuclei are fed from the feeding port, and are continuously and evenly fed to the rack roller through the feeding roller. Three rack rollers rotating in the same direction with different speeds are spaced between the two rollers. The infertile fetuses are shredded in small places, discharged out of the machine through a dust cage (you can also use a straw to connect with a back-end cleaning machine), and then processed into impurities, which can be recycled into cotton linters.

AAADFGTEHTRY