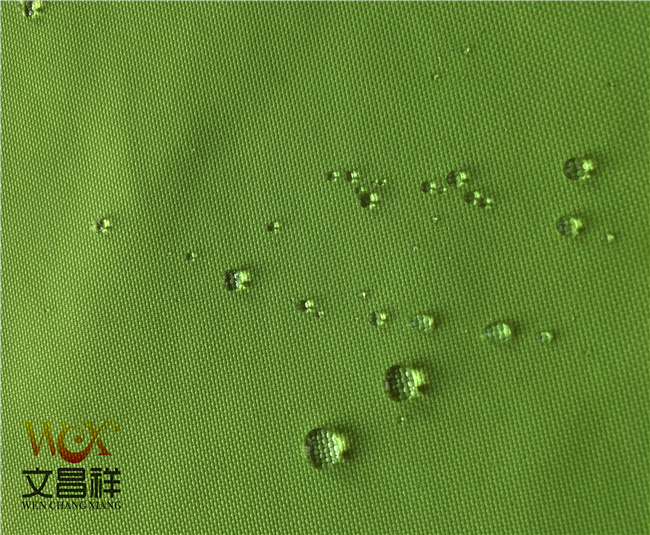

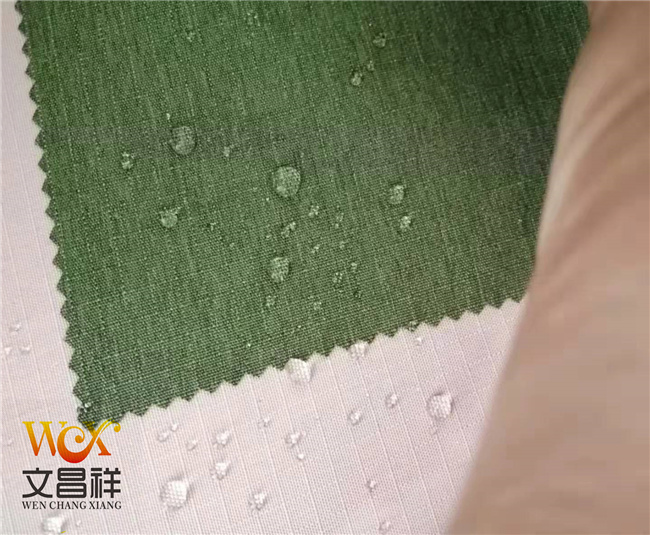

Waterproof Oxford fabric should be interwoven with plain weave on a water-jet loom. After being processed by relaxation, alkali content, dyeing, anti-static, and coating, the gray fabric has waterproof, moisture-permeable, breathable, insulating, windproof, and warmth-keeping properties.

In terms of production technology, the technical requirements of waterproof and breathable fabrics are much higher than those of ordinary waterproof fabrics. At the same time, in terms of quality, waterproof and breathable fabrics also have the same characteristics as other waterproof fabrics. functional features that are not available.

Waterproof Oxford cloth enhances the air tightness of the cloth and While being water-tight, its unique breathable performance can quickly discharge water vapor inside the structure to avoid mold breeding in the structure and keep the human body dry at all times. It perfectly solves the problems of breathability, windproof, waterproof and warmth, and is a healthy and environmentally friendly product. fabric. Now it is widely used in tents, car awnings, train and ship covers, railway and road transportation, warehousing, coal mines, industrial and agricultural fields, etc.

Waterproof Oxford cloth can be waterproof and oil-resistant and UV-resistant. It is generally used in raincoats, umbrellas, home storage, packaging, etc.

Oxford cloth specifications: 1680D, 1200D, 900D , 600D, 420D, 300D, 210D, 150D, etc. Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, pu Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc. .

</p