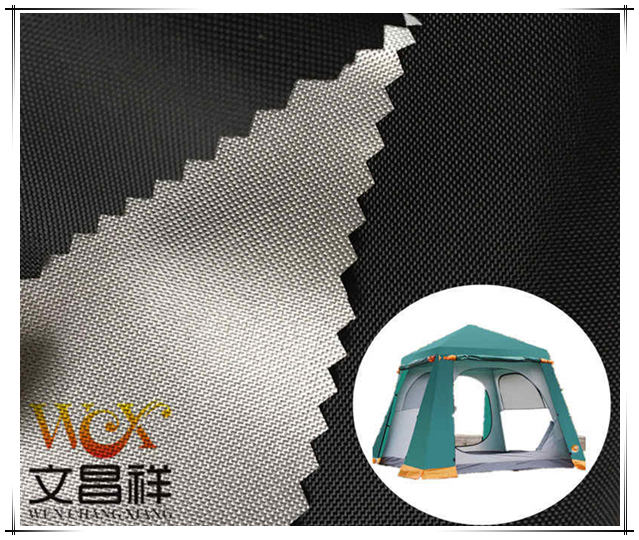

The outdoor tents we have seen are all different, but most of them are made of Oxford cloth. The fabrics used in each part of Oxford cloth are different and can be divided into fabrics, linings, base materials, stays, etc. Different densities and therefore different tensile strengths and waterproofing pressures.

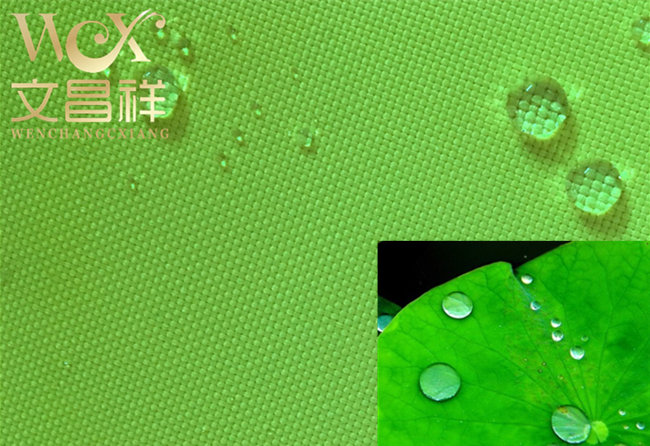

Different fabrics Compared with nylon silk, which is thin and light, suitable for mountaineering and hiking campers, Oxford cloth is thick but relatively heavy, suitable for making tents for driving camping or small groups. From the perspective of waterproof coating, although PVC is good at waterproofing, it also has a disadvantage, that is, it will harden in winter and is prone to creases or breaks. PU coating can not only overcome the shortcomings of PVC, but is also very waterproof. The waterproof pressure of PU with multiple coatings can reach more than 2000MM.

In the tent As for materials, generally choose fabrics that are not prone to mold and can absorb moisture, so nylon is a better choice. The main function of the tent bottom is waterproof, moisture-proof and dust-proof. The choice of base material also determines the grade of the tent. Low-end tents usually use PE as the base material, and PVC is also used. What is sought is low cost and double-sided film-coated PE. Although it has waterproof and moisture-proof functions, it is easy to wear and leak. leak. Winter is the nemesis of PVC base materials, and PU-coated Oxford cloth as the base material greatly exceeds PE in terms of sturdiness, cold resistance, and waterproofness.

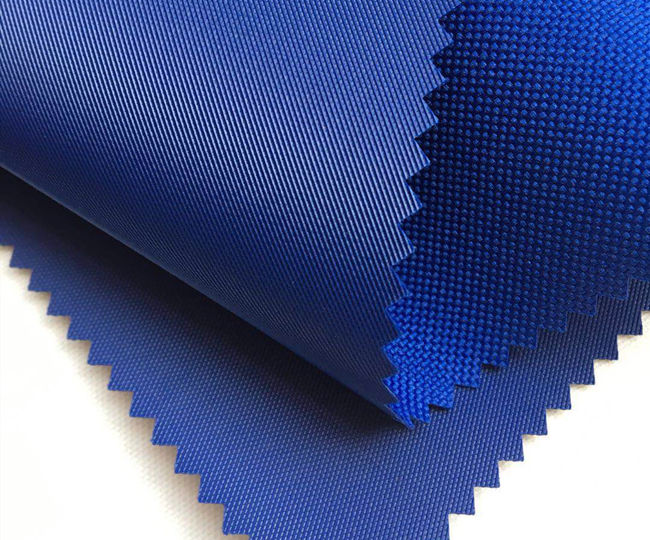

Oxford cloth What are the specifications? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p