The finishing of waterproof fabrics can usually be divided into airtight and breathable according to the breathability of the processed waterproof fabrics. The non-breathable finishing of fabrics is also called coating finishing. It is a continuous film that is non-breathable and insoluble in water and is coated on the surface of the fabric, so the fabric is non-breathable. Wearing clothing made of this kind of fabric will make people feel stuffy, but it can be used to make tents, raincoats and other supplies.

To improve waterproof fabrics To improve the feel, elasticity and durability, most of them are coated with polymer materials that have high adhesion to fabrics, good elasticity, soft feel, and aging resistance. Non-breathable and waterproof finishing is also called water-repellent finishing. It changes the surface properties of fibers and changes the hydrophilicity of the fiber surface to hydrophobicity. However, there are still a large number of gaps between fibers and yarns in waterproof fabrics. Such waterproof fabrics It is both breathable and not easily wetted by water. Water permeability only occurs when the water pressure is considerable, making it suitable for raincoats.

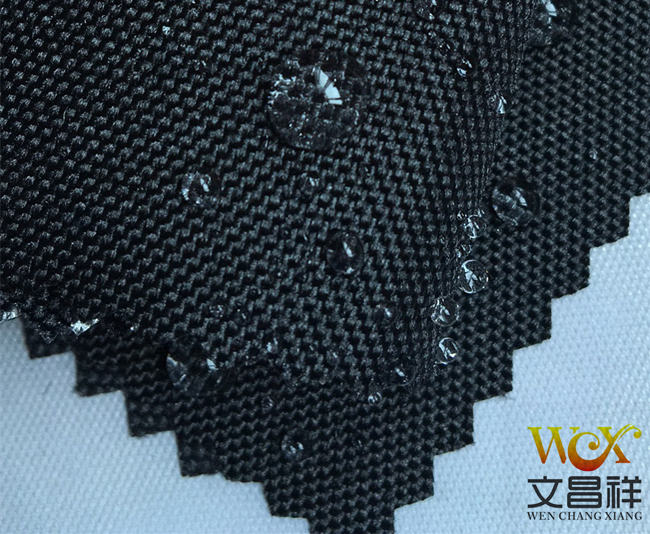

Fabric Water repellency refers to the ability of a fabric to push water droplets away from its surface. The purpose of water-repellent finishing is to prevent water from wetting the fabric and prevent the penetration of liquid water, but still maintain the breathability and moisture permeability of the fabric.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p