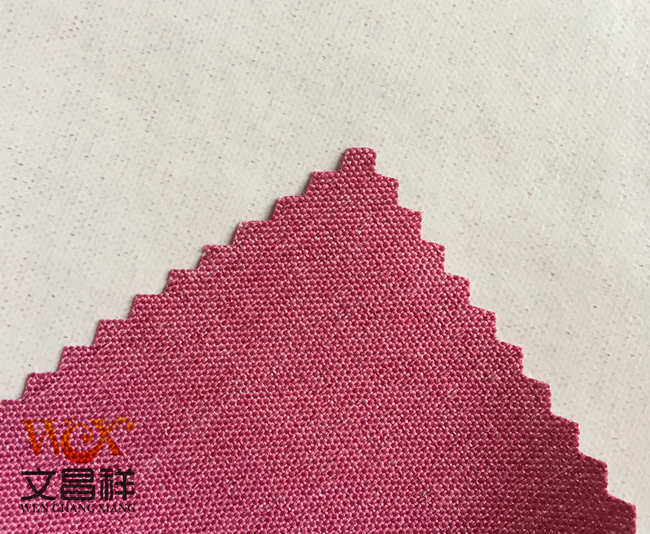

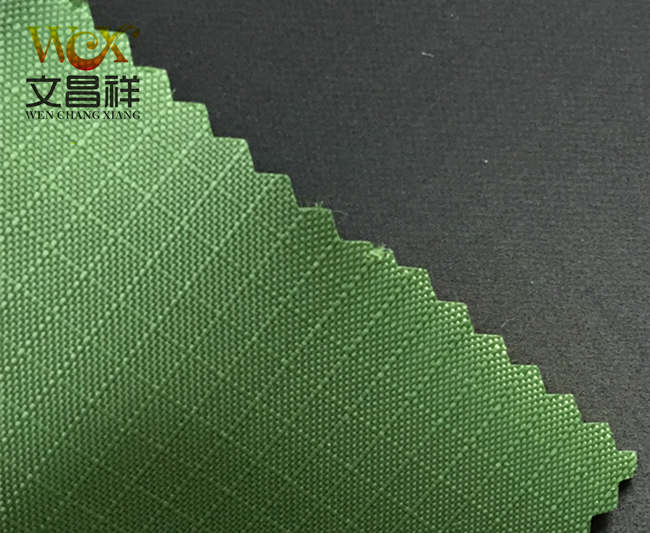

Coated Oxford fabrics are classified according to their functions and characteristics, such as: colored rubber fabrics, PVC-coated fabrics, silver-coated fabrics, calendered fabrics, flame-retardant fabrics, PA breathable fabrics, PU breathable transparent fabrics, etc. Special coated fabrics: rubber-like coating, paper-like processing, waterproof, moisture-permeable and breathable, pearlescent series, oil-wax-like coating, PU gold and silver glue, high water pressure resistance series (up to 1000—10000), UV -CUT anti-UV processing and so on.

Depending on the coating material, Oxford cloth has three categories: PVC, PU and semi-PU coated fabrics. Specifically, the required coating glue particles, such as PU glue, A/C glue, PVC, PE glue points, etc., are dissolved into a saliva-like shape and then evenly applied on the cloth (cotton, polyester, nylon) using a scraper. and other substrates), and then fixed by the temperature in the oven to form a uniform layer of covering glue on the surface of the fabric, thereby achieving waterproof, windproof, breathable and other functions.

Coating Oxford fabric has a wide range of uses and is used in sportswear, down jackets, rainproof parks, jackets, tents, shoes and socks, curtains, bags, as well as ski shirts, mountaineering clothes, windbreakers, etc. with advanced waterproof and moisture-permeable functions. Commonly used fields include: national defense, navigation, fishing, offshore oil wells, transportation, etc.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p