What PVC-coated Oxford cloth and PU-coated Oxford cloth have in common is that they are both coating types. PVC leather and PU leather are collectively called artificial leather. PVC and PU are both polyvinyl chloride. PU feels softer, while PVC feels softer. A bit hard. The difference between the two lies in the manufacturing process.

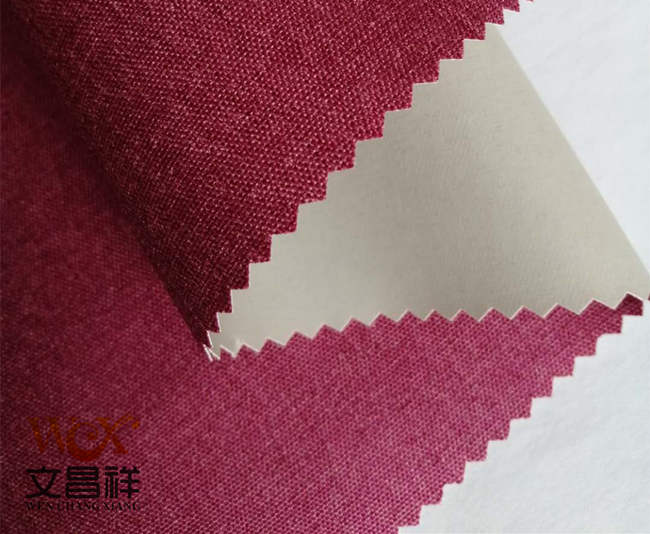

During the manufacturing process of the PVC coating process, the plastic particles are first hot-melted and stirred into a paste, then evenly coated on the Oxford cloth base according to the specified thickness, and then entered into a foaming furnace for foaming , so that it has the softness to adapt to the production of various products and different requirements, and the surface is treated at the same time as it is released.

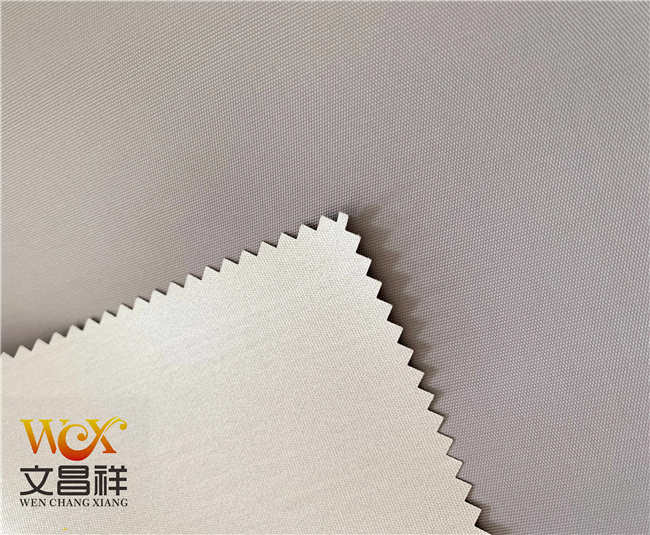

The manufacturing process of PU coating is more complicated than that of PVC leather. Since the PU base fabric has better tensile strength, in addition to being coated on the base fabric, the base fabric can also be included in the middle to make it There is no base fabric visible from the outside. The physical properties of PU leather are better than PVC leather, including resistance to bending, good softness, high tensile strength, and breathability.

The price of PU leather is higher than that of PVC leather. The price of PU leather with certain special requirements is 2-3 times higher than that of PVC leather. Generally, the pattern paper required for PU leather can only be used 4-5 times before being scrapped; the pattern roller has a long service life, so the cost of PU leather is higher than that of PVC leather.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p