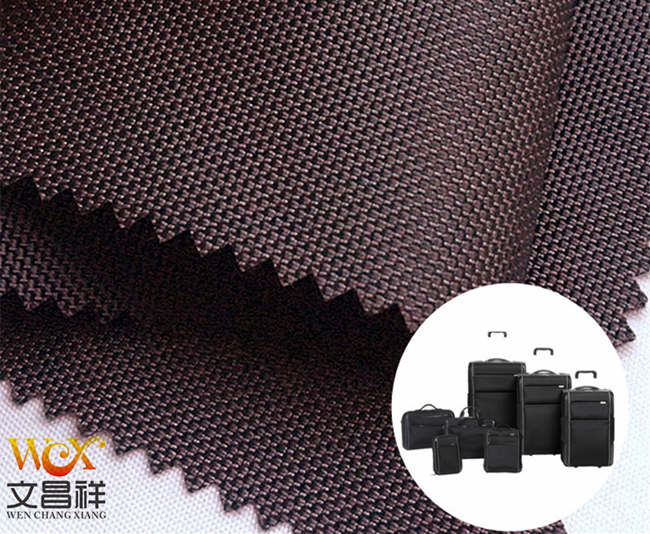

The original raw material used for 1680D double-strand Oxford cloth is nylon, which has the characteristics of strong tensile strength, wear resistance, high density, and good waterproofness. It is made of two 420D nylon yarns that are wound and twisted. It is a twisted 840D silk, because the weaving method is double warp and double weft, and the two 840D silks are 1680D double-ply Oxford cloth.

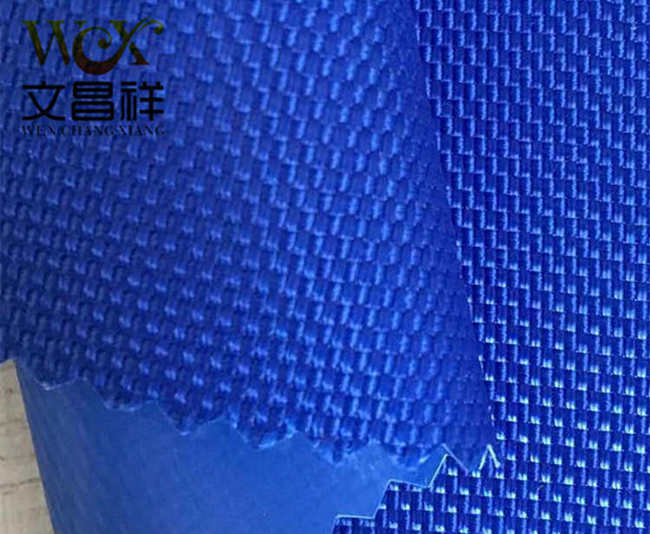

1680D Oxford Fabric finishing is mostly done by calendering PVC, polyurethane, PU coating, EVA composite and other post-processing. There will also be transfer printing, hot rolling, screen printing, etc. After finishing, the 1680D Oxford cloth has a better feel and waterproof performance. better. It also has multiple specifications and style changes, the difference lies in the changes in yarn count density and weight during the weaving process. There are two types of dyeing: liquid cylinder dyeing and flat cylinder dyeing. Liquid cylinder dyeing has high color fastness, small color difference, strong graininess and good gloss.

1680D double-ply Oxford cloth has high tear strength and abrasion resistance, and also has extremely high density and waterproof properties. Its waterproof performance generally reaches the current IPX3 or IPX4 waterproof level. In addition, 1680D double-ply Oxford cloth Oxford cloth has a noble luster, and 1680D material is now generally used as fabric for high-end outdoor products or bags.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p