The most commonly used waterproof fabric testing methods at home and abroad include the American Society for Testing and Materials standard water vapor cup method; the Japanese Industrial Standard testing method. The water vapor cup method test data is also relatively high, and the ASTM standard has naturally become the most commonly used method.

Water vapor pouring cup The test principle is to cover the fabric to be tested on a moisture-permeable cup filled with distilled water, fix it and turn it upside down, weigh it with a top-loading balance with an accuracy of 0.001g, and place it in the position of the wind tunnel row. Before the cup enters an environmental chamber with a temperature of 23°C, a relative humidity of 50%, and a wind speed of 2.5m/s for weighing, record the temperature and relative humidity of the environment. The weight of each cup and the time it took to weigh it were recorded. Record the weight at different times and calculate the water vapor transfer rate using the formula wvt=24*△m/(s*t). The average value of 6 samples is used as the test result. The average value is multiplied by 24 and converted to the result in g/m2*24h.

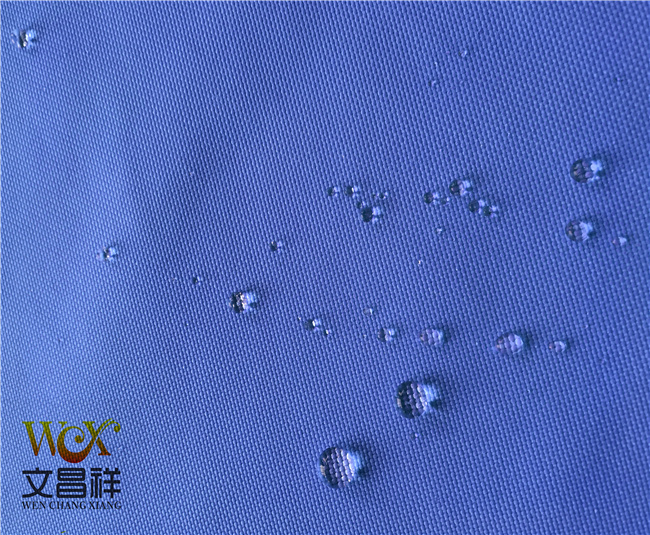

Domestic and foreign The most practical method for testing waterproof fabrics. Most waterproof fabrics that pass these testing methods can achieve waterproof and moisture-proof effects.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, pu Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p