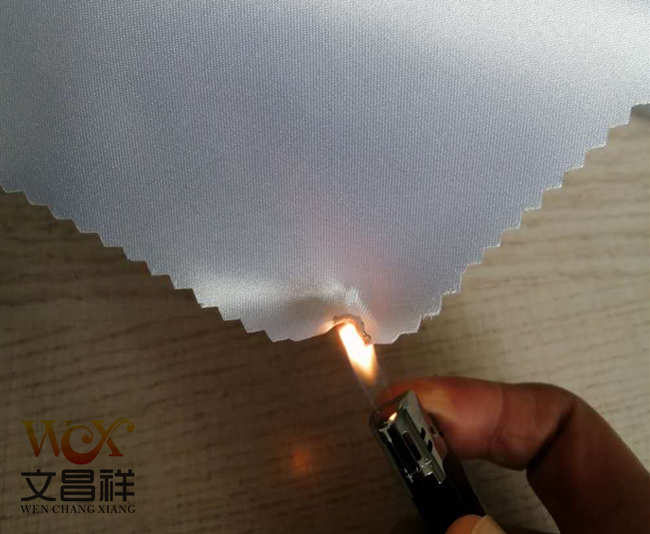

Flame retardant fabric finishing can meet the requirements of different flame retardant degrees and is the most widely used flame retardant method.

Flame retardant fabric finishing generally requires flame retardant particles to be fine, easy to penetrate into fibers, and have strong binding force with fibers. It should have as little impact on the strength, feel and color of the fabric as possible, and have no adverse effects on other additives. Flame retardant finishing can be carried out on existing equipment in printing and dyeing plants. Commonly used methods include: dipping and drying method, padding and baking method, organic solvent method, coating method and spray method.

Coating The flame retardant method is a finishing method in which the flame retardant is mixed into the resin and the flame retardant is fixed on the fabric by resin adhesion. According to the implementation method, it can be subdivided into: scraper method, pouring method, and calendering method.

There are two methods of spraying, one is manual spraying and the other is continuous spraying. The manual spray method is generally used in the last process of textile needle-punched products such as thick curtains and large carpets that cannot be finished with ordinary equipment; the continuous spray method is used for fabrics with fluffy, patterned, tufted or pile-raised surfaces, that is, Not suitable for pad-dried fabrics.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, pu Oxford cloth, Camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p