Fire-resistant fabrics are generally made of non-flammable materials. They are generally resistant to high temperatures and will not cause an open flame if caught on fire. Flame-retardant fabrics add some chemical ingredients to the fabric, which means that some gases produced after burning can separate the fire site from oxygen, thus extinguishing the fire.

Commonly used flame retardant fabrics are divided into post-processed flame retardant fabrics and raw material flame retardant fabrics. Post-processed flame retardant fabrics are mainly: cotton flame retardant fabrics, CVC flame retardant fabrics, C88/N12 cotton nylon retardant Burning fabrics, etc. The raw material flame retardant fabrics are mainly: aramid flame retardant fabrics, acrylic cotton flame retardant fabrics, etc.

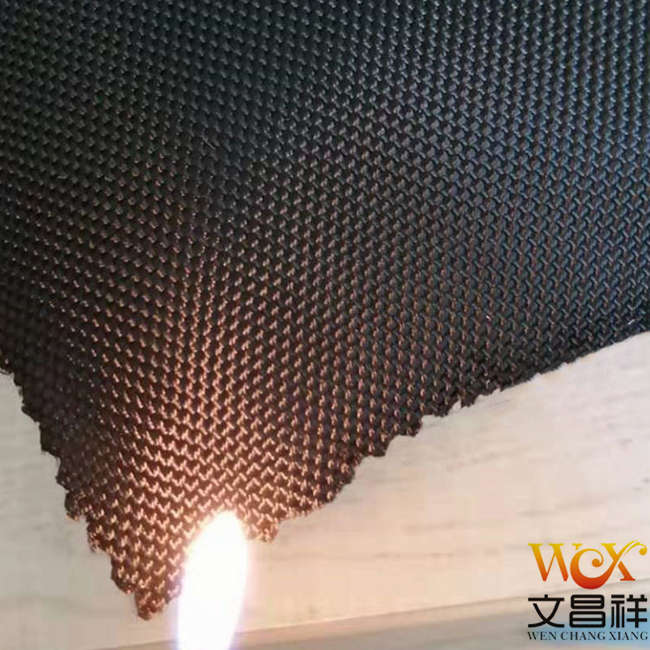

Fire-retardant and flame-retardant fabrics are breathable, moisture-absorbent and quick-drying, soft to the touch and have a soft luster. At the same time, they also retain the anti-static and ecological and environmentally friendly properties of cotton fiber. Protective clothing made of this fabric Comfortable to wear, breathable and moisture-permeable, no irritation to the skin.

Due to the fire-retardant characteristics of flame-retardant fabrics, it is an ideal fabric for making protective clothing in metallurgy, oil fields, coal mines, chemical industry, electric power, and fire-fighting industries.

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., which have temporary flame-retardant effects. Semi-durable flame retardant effect and durable flame retardant effect can also be provided with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the website, or you can Leave a message and we will provide dedicated service to meet all your requirements.

</p