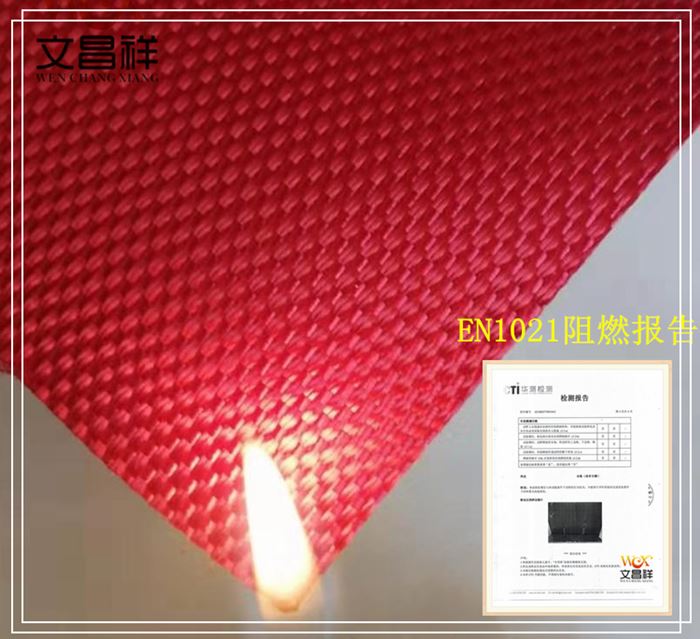

Flame-retardant fabrics are work done in the early stage of the entire cloth-making process. They are mainly made of flame-retardant fibers and are woven into gray fabrics. The flame-retardant effect is durable and can generally be maintained for more than 50 times of washing, regardless of good washing. Effect, especially the flame-retardant yarn used is polypropylene, which shrinks and carbonizes when exposed to fire. It is extinguished as soon as the fire source is removed. It does not melt and cannot produce black smoke, and will not cause secondary fires. It is usually used in clothing fabrics.

GB8965-98 China National Flame-Retardant Clothing Standard The National Bureau of Standards of China promulgated the industrial flame-retardant clothing standard in 1998 with reference to the 1988 standard of the same name and similar international standards. It details the following aspects: Regulations: overall performance of flame-retardant clothing, flame-retardant properties of clothing materials and sutures, mechanical properties of clothing, structural design, processing and production of clothing, finished product marking, packaging and transportation, inspection methods, etc.

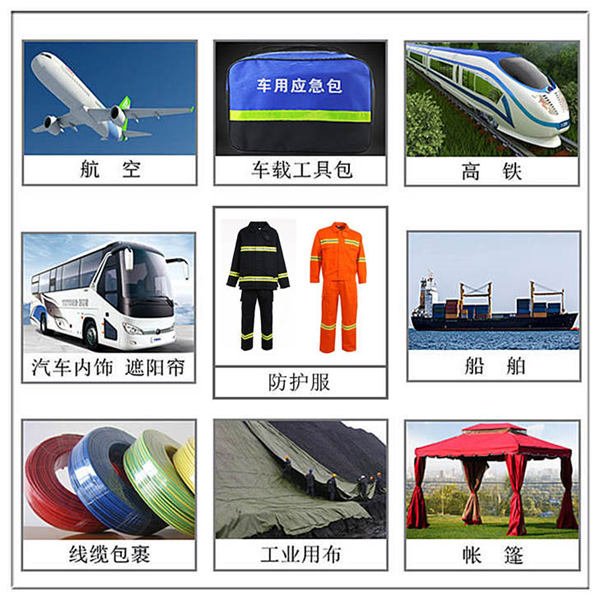

Flame-retardant functional fabrics also have many uses, such as firefighters’ protective clothing and command uniforms; curtains and carpets in homes and hotels; space suits and racing suits.

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., with temporary flame-retardant fabrics. Effect, semi-durable flame retardant effect and durable flame retardant effect. It can also be equipped with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the web page, or You can leave a message and we will provide dedicated service to meet all your requirements.

</p