1. Fire-resistant fabrics are fabrics that cannot burn. Such as: asbestos cloth, glass fiber cloth, etc.

2. Flame-retardant fabrics prevent burning and slow down the burning rate, but will produce carbonization. Commonly used flame-retardant cloths, such as: post-processing include: cotton flame-retardant fabrics, CVC flame retardant fabric, C88/N12 nylon flame retardant fabric, etc. Flame-retardant raw materials include: aramid flame-retardant fabrics, acrylic flame-retardant fabrics, etc.

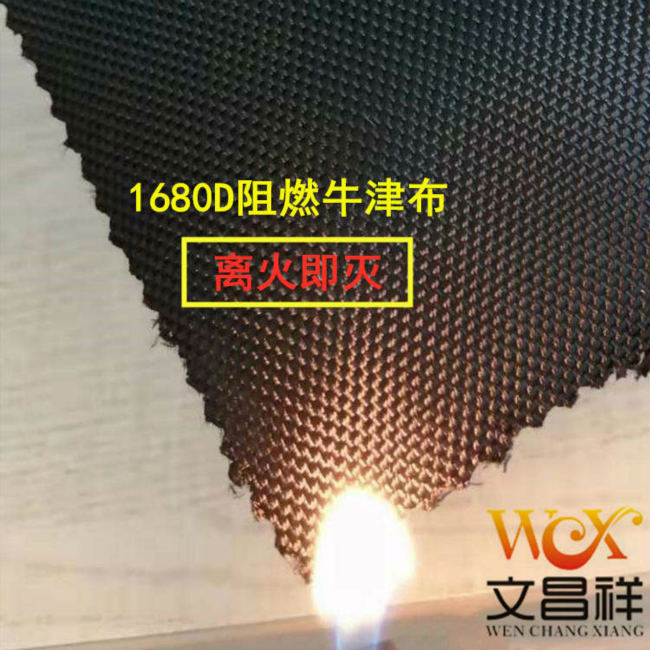

The so-called flame retardant does not mean that the textiles after flame retardant treatment will not burn when exposed to a fire source, but means that the fabric can reduce its flammability in flames, slow down the spread of flames, and not cause a large fire. It burns over an area; and after leaving the flame, it can self-extinguish quickly and no longer burn or smolder.

When a fire breaks out, clothing, curtains, tablecloths and other fabrics are the most likely to cause the fire to expand. With the advancement of technology, more and more functional fabrics are produced, and flame retardant fabric is one of them. The fabrics of these fabrics can effectively prevent fires due to their own characteristics. The familiar firefighters’ fire suits are made of special flame-retardant fabrics.

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., which have temporary flame-retardant effects. Semi-durable flame retardant effect and durable flame retardant effect can also be provided with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the website, or you can Leave a message and we will provide dedicated service to meet all your requirements.

</p