Coated Oxford cloth uses solvent or water to dissolve the required coating particles into a salivary shape, and then evenly coats it on the Oxford cloth in a way, and then fixes it through the temperature in the oven, so that the Oxford cloth A uniform layer of covering glue is formed on the surface of the cloth.

The PU coating can be coated on the top of the base fabric, or the base fabric can be included in the middle so that the existence of the base fabric cannot be seen from the outside. It has excellent mechanical properties such as good physical properties, resistance to bending, good softness, high tensile strength, soft hand feel, good air permeability, and good mold resistance. It is suitable for luggage, clothing, shoemaking, furniture, sports and other industries.

Anti-velvet coating , which refers to the anti-down coating, which can prevent down from running away after coating, and is suitable for making down jacket fabrics. But now the PA coating that requires water pressure to meet standards is also called anti-velvet coating.

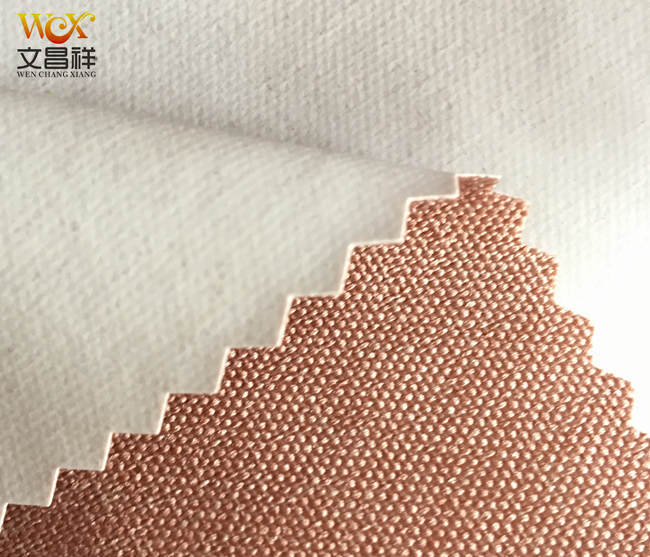

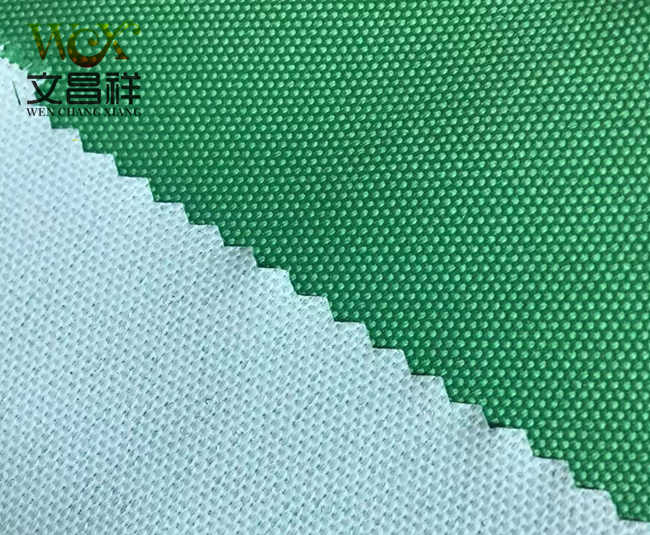

Pearlescent coating, by applying a pearlescent coating on the surface of Oxford cloth, makes the surface of Oxford cloth have a pearl-like luster, which is available in silvery white and colored colors, making the clothing very beautiful. There are also PA pearlescent and PU pearlescent. PU pearlescent is smoother and brighter than PA pearlescent, and has a better film feel.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, pu Oxford cloth, Camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p